Description

USE: Liquid transport in: -irrigation; -livestock; -construction sites.

REVIEW: Made of certified DC01steel, pipes are drawn in our workshops and soldered using automatic machines. Items are cut according to customers requirements and then are subjected to the Tightness test pressure on CNC testing facilities. The joints are printed from DD11 pickled steel by molds with mechanical presses up to 500 tons. Robot welders provide for the welding by inverter generators. The galvanization process is preceded by a salt bath in order to eliminate any possible superficial impurity contained in the product. Vertical galvanizing well is probably the only one in Europe and it is specifically designed for thin-walled pipes galvanizing – in service 24 hours a day, 365 days a year – with its 458 ° C operating temperature, provides an optimal grip of the mixture of zinc on the steel bottom. Another distinctive feature of the quality of the protective treatment is the use of virgin electrolytic zinc which purity is certified at 99.995%

250 and 300 diameters are provided with a removable locking lever of increased length in order to facilitate the proper closure.

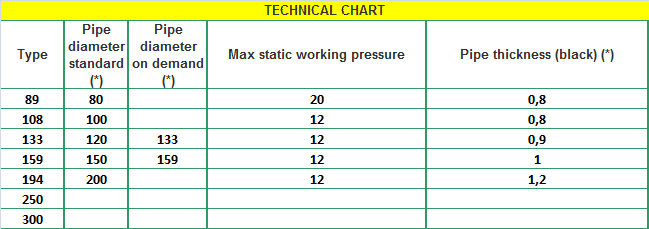

*tolerances are applie

Related Products

-

Galvanized steel pipes with Robur quick couplings

-

Galvanized steel pipes with Ferrari quick couplings

-

Galvanized steel pipes with Hydraulic quick couplings

-

Galvanized steel pipes with Anfor quick couplings

-

Galvanized steel pipes with type Bauer quick couplings

Reviews

There are no reviews yet.