Irrigation industries

Irrigation System and Water Transfer

Agriculture

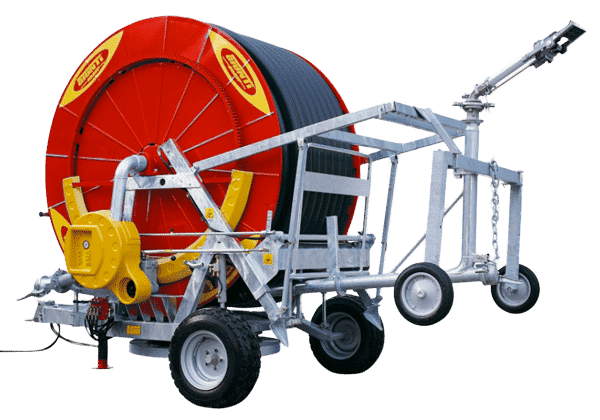

Traveller hose-reel machines

Accessories for hose-reel machines

Spray booms

Filtering stations

Drip tapes

Pumping stations for irrigation

Generator sets

Iron galvanized pipes

Equipment for networks

Industry

Wellpoint equipment

Pumping stations for industry

Generator sets

GALVANIZED PIPES

Produced using steels of the best quality they are subsequently protected against corrosion by hot-dip galvanization. They are assembled together to quick couplings and can reach up to 400 millimeters of diamter. The specific purpose they will be used identify which kind of joint to use, even based on maximum working pressure needs.

WELLPOINT & WATER TRANSFER

The wellpoint equipment exploits a fast and flexible system of pipes used in digging places with groundwaters. The lowering of aquifer level is made by the insert of filtering needles which allow the realization of works in comfortable way. The term water transfer identifies the drainage of water in general, waters existing in sites are conducted out of there by forced channeling.

PUMPING UNITS

Each need can be covered thanks to the wide range of available centrifugal pumps, both for irigation and industrial applications. The models are classified for water class, energy supply type, positioning, flow and pressure working conditions. The most suitable product for the specific application is often delegated to the technical sector that evaluates the most suitable product.

IRRIGATION TRAVELLER MACHINES

These machines spread the rain on the field through sprinklers working at medium pressure and having long casting range. The guns are continuously moved on the field by trolley and rewind thanks to the same hydraulic power. Even the coverage of big surfaces is made in fast and cheap way. The rain is well distributed through all the areas.

IRRIGATION WATER FILTERS

Are made of iron steel, protected against corrosion, by painting process or phosphating anticorrosion procedure and final hot-dip galvanization. They purify the water from impurities, allowing the usage of same water for irrigation purposes. The choice of model is based on the amount of water applied, water source, pressure characteristics. Filtering capacity depends on the selected model. Compatible with fertigation.

MICRO IRRIGATION

The plastic emitters let drop each short interval of time, low quantities of water directly over the roots surface. The emitters work at low pressure, with flows range of few liters per hour, the water distribution is optimal, as well the humidity control of the soil.

Would you like to know more? Register by filling out the form

the countries in the world where the Giunti Group export its products

the millions of meters of galvanized pipes produced

the number of items always available in our main warehouse

Why choose Giunti S.p.A.?

For many reasons…

High specialization

Because since when the Company was born, the only focus business was the pumping, transportation and distribution of the water, both in industrial purposes and agricultural irrigation, always aiming for the excellence

Expert management

Because the leadership of the Company is still in the hands of the Giunti family whish started the activity over 70 years ago

Continuous update

Because our people every year spend time for improvement of its own knowledge, then transferring the new competencies and technologies to our partners

Unique patents

Because many of our products have international patents, and many of them are identified and guaranteed by registered trademark

Trust

Because loyalty and fairness of business relationships are a company goal, which aims to create long-lasting cooperation with all our partners

Collaborative development

Because our products are developed together to our customers

Innovation and research

Because we have found our success on continuous innovation and research

Respect of timetables

Because our products arrive in your hands in time

Top assistance

Because we provide our customers assistance service before, during, and after the sale

Careful for the environment

Because our development follow also criteria of energy saving and environment sustainability

Gallery

Confindustria

Umbria Export

Agrimech Umbria

la partecipazione ad EIMA 2016 è stata realizzata con il contributo di Regione Umbria e Sviluppumbria, a valere su fondi comunitari (POR FESR 2014 – 2020)

Research Scientific Report on Industrial Research and Experimental Development project

Research and development of an advanced production system for the field of galvanization able to guarantee the recovery of metallic zinc from solutions remaining from the stripping process to re-employ for galvanizing of pieces for optimization of management costs and reduction of environmental impact.